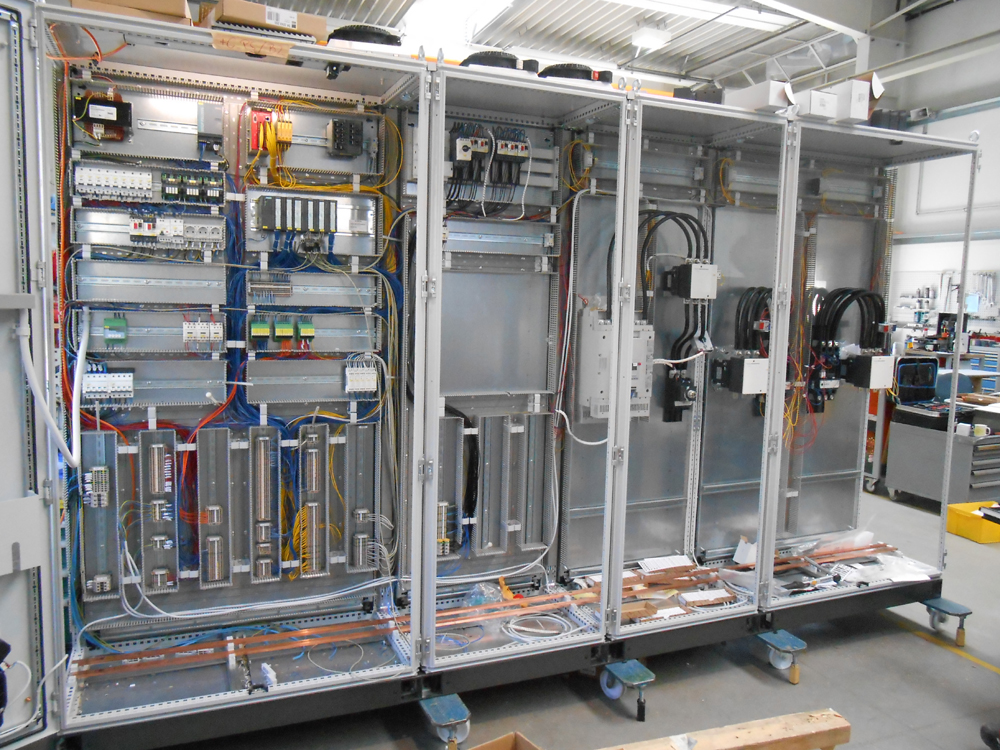

Cement and Minerals Control System

We provide engineering and comissioning support for DCS system. We can upgrade the existing system with latest technologies available in the market.

Safety Instrumented system Automation

Chemical, Non chemical, Gas, Mining, and other Process plants needs a safe and secured operation of the plant. The normal process design gives the basics protection to the complete process operation , the basic process control is installed with instruments, alarms, monitoring .The level, flow and pressure sensors and the final control element are operated based on the basic logic controller PLC/ DCS.

Functional safety is a central important to the process industry, a failure in instrument relevant to safety may have relevant consequence

Chemical, Petrochemical, Mining, Gas Compression , and many other manufacturing plants has risk working location, Risk due to Fire Explosion, gas release , tank overflow, chemical exposure etc. The only way to eliminate the risk is, not to build or stop operating these types of industries, but it is not possible, because they produce products useful and important in everyday life.

Even a simple product like Laundry detergent is made via a process that includes , pumping liquids at high pressure, spring droplets in high temperature air and finally collecting the process in a very dusty environment which causes inhalation risk.

In order to minimize the risk, process control system are installed to maintain a safe operation of plant assisted by robust alarm detection and reporting system operated by trained operators, but often these measures alone cannot reduce the risk of injury due to fire , explosion to a tolerable level.

During process design, care is taken to specific lines, equipment’s, valves with correct sizes and material of construction and proper accessories.

The Basic process control system is installed with appropriate instruments controls and monitoring logic to allow the plant to be operated with in the safest range of temperature , pressure, level, and flow rates.

Alarms are configured to allow the operator to react on abnormal conditions and take necessary corrective actions before an risk becomes and accident.

The American safety standard ISA and European Safety standard IEC together became ISA 84 IEC 61508 , This safety procedures are developed on the concept of functional safety.

Safety Instrumented system has sensors controllers and final control element similar to normal process control system, BUT SIS is a separate set of devices , they cannot be interlinked with the normal process controller, The logic solver is a specialized hardened safety PLC like device may have multiple processor executing the logic in parallel to ensure the integrity of logic and resulting action.

SIS is designed around individual Functions in the plant called SIF, the logic solve takes the SIS inputs and determines what SIS output should be for the SIF.

Normally A safety system has complete redundant system, redundancy is like 2 out of 3 or 1 out of 2 system, The 2 out of 3 system is highly expensive but more reliable system.

Rolling mills and Vertical Mills Automation

WE are expertise in supply of Control systems for grinding mills supplied by the leading mill manufacturers around the globe. Each Mill manufacturers have their own protocols for the mill operation, the manufacturer’s Flow diagram is strictly followed and the logics are developed for the successful commissioning.

Our mill logic controller can be operated from the Main Control room as well as from Local Control panel for Maintenance operation with the access permission from the control room with all safety ensured.

Bag house Controll Automation

The dust in cement and other minerals process plants are collected using bag house, collected dust material is taken in to process again and the dust emission to atmosphere is controlled.

The Manufacturers have different modes of operation, we take all the modes in to account and safe operational control system is designed and supplied.

Material Handling Automation

The Raw material has to be Stored and Reclaimed in all the process plants, they use heavy machines to transport huge amount of material, and we completely study the operation of the machines and develop the logic as per the flow chart and operational procedures of the manufactures.

Ware house Automation

The different types of end products are transported stored, The stock details are maintained and displayed for each individual products respectively and the product details are integrated to the management information servers so the management get the data whenever required for data analysis.